BYD is investing in its production for the blade battery technology in Chongqing, China. After the ramp-up, a total output of 20 GWh per year was announced by BYD. To achieve this goal, 8 new production lines will be opened in the upcoming months. 20 GWh capacity per year is enough to supply around 400.000 electric cars with 50 kWh capacity each.

The investment sum amounts to around $1.4 bn. In March 2020 the blde battery production was started. More than 100 media and industry experts were invited to tour the factory called FinDreams.

BYD is betting big on its blade technology based on the LFP-chemistry. LFP stands for lithium-iron-phosphate and is more popular in China. Tesla is using LFP-batteries for parts of the production of the Model 3 assembled in the Shanghai factory since 2019. This announcement also attracted media and investors’ attention in North America and Europe since then.

With this investment, we assume that BYD’s LFP battery proportion grew significantly in 2020.

BYD Blade Battery Technology

The specs of the BYD blade battery technology look promising.

BYD blade battery cell specs

- Cell type: Prismatic

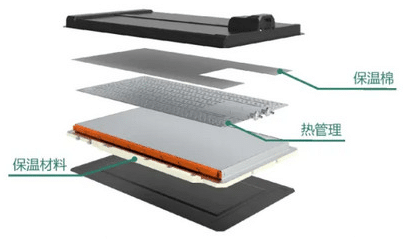

- Battery design: Cell to pack (no separate modules)

- Cell chemistry: LiFePO4 (LFP)

- Cell dimensions: 905 mm (length) x 118 mm (height) x 13,5 mm (width)

- Nominal voltage: 3.2 V

- Max. Voltage: 3.65 V

- Capacity: 202 Ah

- Energy: 646 Wh (3.2 V x 202 Ah)

- Volumetric energy density: 448 Wh/L

- Gravimetric cell-to-pack ratio: 86%

Even though the energy density on the cell- and pack level can’t compete with NCA or NCM-based batteries, BYD made good progress with its blade technology. The company is using a “no-modules” design called CTP (Cell to pack) technology. The CTP approach saves weight and space compared to using several modules within the battery pack so that the overall density can be attractive for application in EVs. It is also important to state that CTP technology reduces costs significantly.

An important advantage of the LFP-chemistry is also the safety of the chemistry. The blade battery is less susceptible to catch fire as several tests showed so far. Additionally, according to BYD’s announcement, the battery has high longevity. Cycling tests show that 3.000 cycles are achievable, however with no SOH (State of Health) data for the cycle tests provided. Overall, 3.000 cycles amount to more than 1 million km.

Lastly to mention is the cobalt-free design. Not only does this reduce cost, but it is also advantageous from a sustainable perspective. We assume that the sustainability of batteries is becoming more important, so the LFP-based blade technology could be a good alternative to conventional NCx technologies.

Application of blade technology in EVs

The BYD Han is the first car to use blade technology. The vehicle is first being sold in China before also coming to Europe. The specifications look promising, as the BYD Han:

- is rated with a range of up to 605 km / 375 miles according to NEDC

- can be charged from 10% – 80% of capacity in about 30 minutes

- 0 to 100km/h in 3.9 seconds

BYD is listed on the Hong Kong and Shenzhen Stock Exchanges.