On October 20, the Hummer EV 2022 was officially presented by GMC. This is a fully electric-powered truck with 1,000 hp. At GoSaveTime we introduce the Hummer EV battery specifications. The sections are divided into technical battery specifications and performance values.

Technical data: Hummer EV Battery Specifications

Battery pack

- GM Hummer EV vehicle platform: BEV3 architecture

- Battery platform type: skateboard

- BMS (battery management system): Wireless (WBMS)

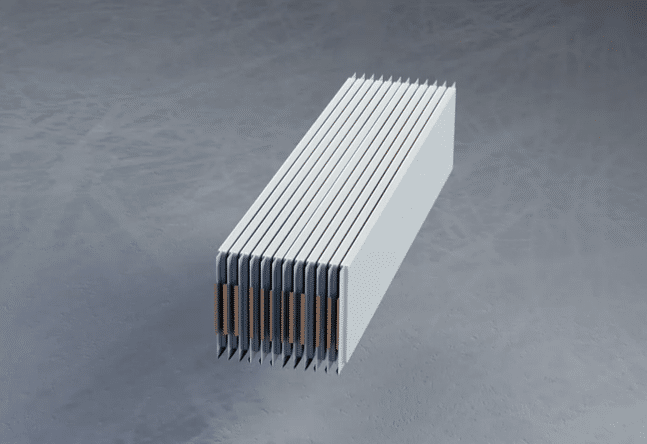

- Number of battery modules: 12 x 2 (Double stacked batterie modules)

- Capacity: 200.0-kWh battery

- Normal system voltage: 400 V system

- Charging voltage: 800 V (charging rate of 200 kW for 400 V, and 350 kW for 800 V DC charging)

Chemistry and cell design

- Battery cell chemistry: NCMA (nickel, cobalt, manganese, aluminum)

- Cell format: Pouch cells (Tesla uses cylindrical cells mostly)

Production

- Battery cell supplier: LG Chem

- Annual battery production capacity: 30 GWh p.a. (planned)

- Battery factory location: Ohio, USA

Cell design and chemistry

- Cell format: Pouch cells (Tesla uses cylindrical cells mostly)

- Battery cell chemistry: NCMA (nickel, cobalt, manganese, aluminum)

GMC relies on the Ultium battery cells, introduced a few months ago. The cell supplier will be the South Korean battery giant LG Chem.

The cell chemistry is NCMA. This is in line with LG’s battery roadmap: The cell supplier has foreseen in its schedule to accelerate the introduction of NCMA-based batteries and possibly introduce them already in 2021, one year earlier than planned.

As demonstrated with the MEB battery, GM also plans to introduce prismatic battery cells in its battery architecture. It is conceivable that other cell suppliers could be used in certain regions. The flexibility in cell format is an advantage for selecting suppliers.

World first: According to GM, the BMS is already wireless in the Hummer EV. Some time ago, GM already announced that they use wireless modules in the Ultium batteries. The BMS slaves transfer information from the cells and modules to the BMS Master, which controls the overall battery pack. Up to now, you will find physical cables in series production vehicles – also for safety reasons. GM is pursuing a path with its WBMS that offers three decisive advantages by reducing Battery cabling by up to 80%. On the one hand, this saves weight and, on the other hand, offers optimization potential in terms of available battery space utilization. Furthermore, it reduces the total cost of the battery.

GM plans to reduce the cost of the battery pack (not cells) to reach less than 100 USD/kWh in the coming years. 100 USD/kWh is a big step forward and also in line with the plans of other major car manufacturers.

Performance battery data for the Hummer EV

- Range: 350 miles

- Charging:

- Maximum of 100 miles of range in 10 minutes (at 350 kW charging power)

- 80-percent charge to be completed in less than 30 minutes

- Speed: 0-60 mph sprint of 3.0 seconds

How does the EV Hummer compare with the Rivian R1T and Tesla Cybertruck?

Please find more images on the official GMC EV Hummer website.